Dip Seal Plastics is a leading provider of durable plastic coatings and reliable melting tank solutions. Our plastic coatings are applied through a specialized dipping process, offering superior protection against corrosion, electrical issues, and enhancing the appearance of various materials. With customizable options and a focus on customer satisfaction, Dip Seal's coatings are trusted by industries across different sectors.

In addition to our plastic coatings, Dip Seal manufactures advanced melting tanks that ensure efficient and precise melting of materials such as waxes, adhesives, and resins. Constructed with high-quality materials and equipped with cutting-edge heating technology, Dip Seal's melting tanks provide industries with reliable temperature control for our melting processes. With a commitment to innovation and customer-centric solutions, Dip Seal remains a trusted partner for businesses seeking top-notch plastic coatings and melting tank solutions.

About Us

Incorporated in 1949, Dip Seal Plastics, Inc. has been a family owned business for more than 70 years. Our staff takes pride in their ability to come up with solutions for a customer's problem. Our technical and customer service are world class. Our mission is always to look for better ways to provide you the best in quality and service, while continuing to provide the most effective thermal plastic protective and decorative coating possible.

Plastic Protective Coatings - Quick Links

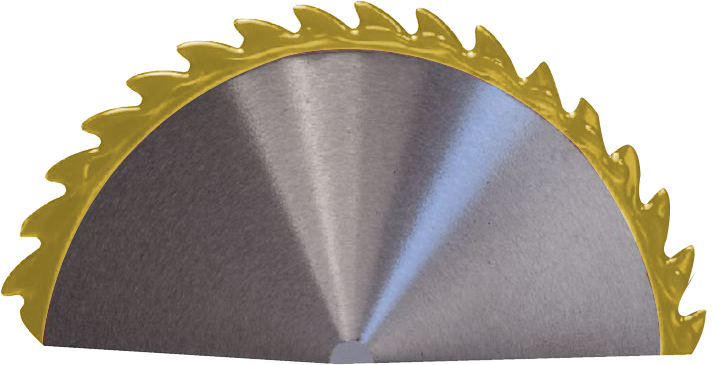

wax melters and dipping tanks plastic dip coating liquid plastic dip coating hot melt wax coating strippable protective coatings dipping tank suppliers table saw protective coatings

Plastic Tool Dip Coating Services

DipSeal's specialized plastic tool dip coating service offers comprehensive benefits. It provides advanced protection, shielding tools from impact, abrasion, corrosion, chemicals, and harsh weather. The coating enhances grip and ergonomic comfort, ensuring safe handling in challenging conditions. Additionally, DipSeal offers reliable electrical insulation crucial for tools used in electrical work, along with distinctive color options for easy tool identification. Tailored customization options align with specific preferences or branding needs, while the robust protective layer enhances tool durability and lifespan, ensuring sustained performance across various industries.

Plastic Rubber Dip

At DipSeal, our plastic rubber dip serves as a versatile solution tailored for enhancing tools' performance and longevity across diverse industries. With our specialized coating, tools are shielded from impacts, abrasions, corrosion, chemicals, and harsh weather conditions, ensuring extended lifespan and optimal functionality. The rubberized coating not only improves grip and handling, even in challenging environments, but also provides essential electrical insulation for tools used in electrical work, preventing potential hazards. Moreover, our rubber dip offers customization options with various colors and textures, facilitating easy tool identification and alignment with specific branding needs. Through DipSeal's comprehensive solution, clients benefit from enhanced tool comfort, safety, and durability, empowering efficient operations in any work setting.

Liquid Plastic Dip Solutions

Liquid plastic dip, specifically formulated for tool coating applications, provides a versatile protective solution that safeguards tools against impacts, abrasions, corrosion, chemicals, UV rays, and weathering. Its waterproofing properties prevent moisture damage, while certain formulations offer electrical insulation for enhanced safety during tool usage. Additionally, the coating enhances grip and comfort on tool handles, reducing slippage and fatigue. Available in various colors and finishes, it allows for customization to match individual preferences or branding requirements. Moreover, its peelable or removable nature facilitates easy repair or replacement without harming the underlying tool surface, making it an indispensable choice for enhancing tool durability, safety, and usability in diverse industrial, automotive, or DIY settings.